Fibreglass Grating

Products

#shopify-section-pservice_2 #block-f6dde8ae-06d3-43a9-946e-1dffb196803c {

margin: auto;

padding: 0;

}

@media(max-width: 991px) {

#shopify-section-pservice_2 #block-f6dde8ae-06d3-43a9-946e-1dffb196803c {

margin: 0;

padding: 0;

}

}

@media(max-width: 767px) {

#shopify-section-pservice_2 #block-f6dde8ae-06d3-43a9-946e-1dffb196803c {

margin: 0;

padding: 0;

}

}

#shopify-section-pservice_2 #block-f6dde8ae-06d3-43a9-946e-1dffb196803c .addon-menu ul.circled li.bg { line-height: 36px; background: #f4f6f8; }

#shopify-section-pservice_2 #block-f6dde8ae-06d3-43a9-946e-1dffb196803c .addon-menu ul.circled li.bg:hover,

#shopify-section-pservice_2 #block-f6dde8ae-06d3-43a9-946e-1dffb196803c .addon-menu ul.circled li.bg:focus,

#shopify-section-pservice_2 #block-f6dde8ae-06d3-43a9-946e-1dffb196803c .addon-menu ul.circled li.bg:active { background: #e40425; }

#shopify-section-pservice_2 #block-f6dde8ae-06d3-43a9-946e-1dffb196803c .addon-menu ul.circled li.bg:before { color: #e40425; }

#shopify-section-pservice_2 #block-f6dde8ae-06d3-43a9-946e-1dffb196803c .addon-menu ul.circled li.bg:hover:before,

#shopify-section-pservice_2 #block-f6dde8ae-06d3-43a9-946e-1dffb196803c .addon-menu ul.circled li.bg:focus:before,

#shopify-section-pservice_2 #block-f6dde8ae-06d3-43a9-946e-1dffb196803c .addon-menu ul.circled li.bg:active:before { color: #ffffff; }

#shopify-section-pservice_2 #block-f6dde8ae-06d3-43a9-946e-1dffb196803c .addon-menu ul.circled li.bg a { color: #32373c; }

#shopify-section-pservice_2 #block-f6dde8ae-06d3-43a9-946e-1dffb196803c .addon-menu ul.circled li.bg:hover a,

#shopify-section-pservice_2 #block-f6dde8ae-06d3-43a9-946e-1dffb196803c .addon-menu ul.circled li.bg:focus a,

#shopify-section-pservice_2 #block-f6dde8ae-06d3-43a9-946e-1dffb196803c .addon-menu ul.circled li.bg:active a { color: #ffffff; }

#shopify-section-pservice_2 #block-5a6cd6c2-37a8-4ed6-9b22-515e87ea82c4 {

margin: auto;

padding: 0;

}

@media(max-width: 991px) {

#shopify-section-pservice_2 #block-5a6cd6c2-37a8-4ed6-9b22-515e87ea82c4 {

margin: 0;

padding: 0;

}

}

@media(max-width: 767px) {

#shopify-section-pservice_2 #block-5a6cd6c2-37a8-4ed6-9b22-515e87ea82c4 {

margin: 0;

padding: 0;

}

}

#shopify-section-pservice_2 #block-5a6cd6c2-37a8-4ed6-9b22-515e87ea82c4 {

color: #211212;

font-size: 32px;

font-weight: 400;

line-height: 24px;

letter-spacing: 0px;

border-radius: 0px;

}

@media(max-width: 991px) {

#shopify-section-pservice_2 #block-5a6cd6c2-37a8-4ed6-9b22-515e87ea82c4 { font-size: 14px; line-height: 24px; }

}

@media(max-width: 767px) {

#shopify-section-pservice_2 #block-5a6cd6c2-37a8-4ed6-9b22-515e87ea82c4 { font-size: 30px; line-height: 24px; }

}

#shopify-section-pservice_2 #block-5a6cd6c2-37a8-4ed6-9b22-515e87ea82c4:hover,

#shopify-section-pservice_2 #block-5a6cd6c2-37a8-4ed6-9b22-515e87ea82c4:focus,

#shopify-section-pservice_2 #block-5a6cd6c2-37a8-4ed6-9b22-515e87ea82c4:active {

background-color: ;

border-color: ;

color: ;

}

#shopify-section-pservice_2 #block-5a6cd6c2-37a8-4ed6-9b22-515e87ea82c4 .addon-heading,

#shopify-section-pservice_2 #block-5a6cd6c2-37a8-4ed6-9b22-515e87ea82c4 a { color: inherit; font-size: inherit; font-weight: inherit; line-height: inherit; text-transform: inherit; }

Fibreglass Grating

#shopify-section-pservice_2 #block-6678384e-1f4c-4405-9dec-79a1e43230f8 {

margin: auto;

padding: 0;

}

@media(max-width: 991px) {

#shopify-section-pservice_2 #block-6678384e-1f4c-4405-9dec-79a1e43230f8 {

margin: 0;

padding: 0;

}

}

@media(max-width: 767px) {

#shopify-section-pservice_2 #block-6678384e-1f4c-4405-9dec-79a1e43230f8 {

margin: 0;

padding: 0;

}

}

#shopify-section-pservice_2 #block-6678384e-1f4c-4405-9dec-79a1e43230f8 .addon-line span {

display: inline-block;

width: 30px;

height: 2px;

background: #e40425;

}

#shopify-section-pservice_2 #block-c04f57dc-9187-4c17-bf1c-a81ae81cea11 {

margin: auto;

padding: 0;

}

@media(max-width: 991px) {

#shopify-section-pservice_2 #block-c04f57dc-9187-4c17-bf1c-a81ae81cea11 {

margin: 0;

padding: 0;

}

}

@media(max-width: 767px) {

#shopify-section-pservice_2 #block-c04f57dc-9187-4c17-bf1c-a81ae81cea11 {

margin: 0;

padding: 0;

}

}

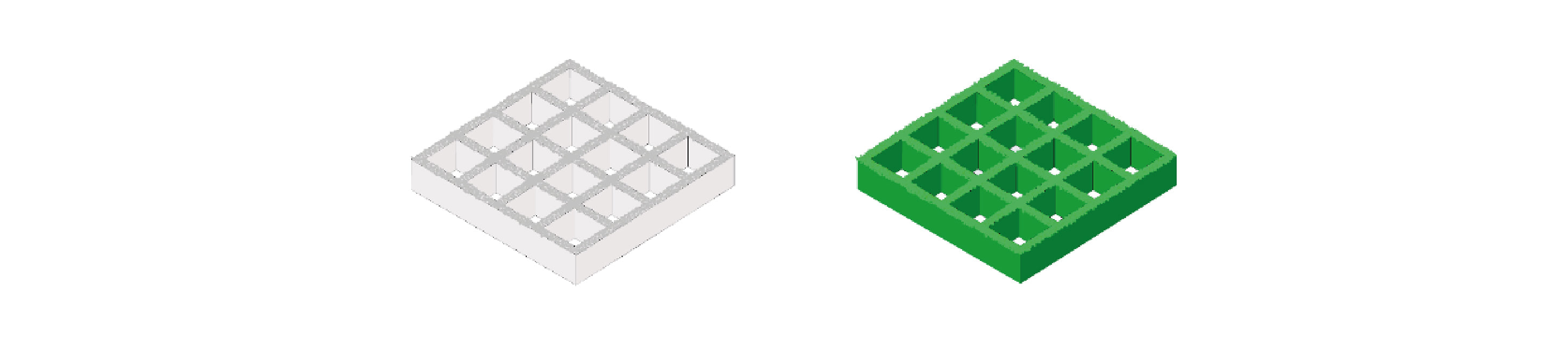

The Magnus Group’s Fibreglass Grating is manufactured in an open, heated mold system.

Continuous rovings are placed in the mold in alternating layers and completely wetted out with resin and hot curing.

There are several fibreglass grating molds available resulting in an extensive range of thicknesses, mesh patterns and panel sizes.

We carry a large quantity of stock of Fibreglass Grating and can provide our customers with the following resin systems:

- Isophalic Polyester (Green and Light Grey)

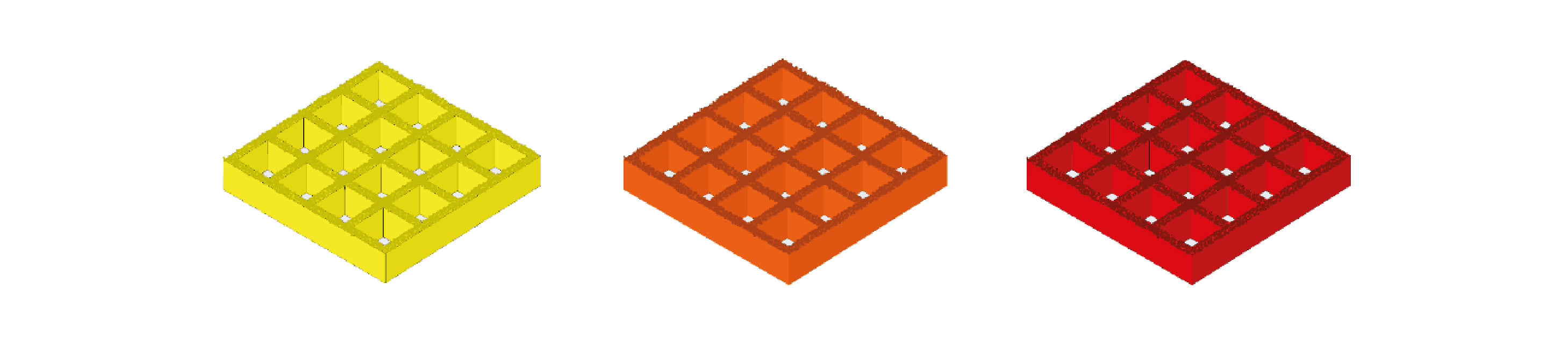

- Vinyl Ester (Orange, Yellow, Red)

The Magnus Group can supply fibreglass grating panels in the following sizes:

- 2440 x 1220

- 3660 x 1220

Thicknesses of fibreglass grating on offer include:

- 25mm

- 30mm

- 38mm

- 50mm

#shopify-section-pservice_2 #block-9fb7ae11-8567-470a-b838-708cd2da4546 {

margin: auto;

padding: 0;

}

@media(max-width: 991px) {

#shopify-section-pservice_2 #block-9fb7ae11-8567-470a-b838-708cd2da4546 {

margin: 0;

padding: 0;

}

}

@media(max-width: 767px) {

#shopify-section-pservice_2 #block-9fb7ae11-8567-470a-b838-708cd2da4546 {

margin: 0;

padding: 0;

}

}

#shopify-section-pservice_2 #block-9fb7ae11-8567-470a-b838-708cd2da4546 {

color: ;

font-size: 14px;

font-weight: 400;

line-height: 24px;

letter-spacing: 0px;

border-radius: 0px;

}

@media(max-width: 991px) {

#shopify-section-pservice_2 #block-9fb7ae11-8567-470a-b838-708cd2da4546 { font-size: 14px; line-height: 24px; }

}

@media(max-width: 767px) {

#shopify-section-pservice_2 #block-9fb7ae11-8567-470a-b838-708cd2da4546 { font-size: 14px; line-height: 24px; }

}

#shopify-section-pservice_2 #block-9fb7ae11-8567-470a-b838-708cd2da4546:hover,

#shopify-section-pservice_2 #block-9fb7ae11-8567-470a-b838-708cd2da4546:focus,

#shopify-section-pservice_2 #block-9fb7ae11-8567-470a-b838-708cd2da4546:active {

background-color: ;

border-color: ;

color: ;

}

#shopify-section-pservice_2 #block-9fb7ae11-8567-470a-b838-708cd2da4546 .addon-heading,

#shopify-section-pservice_2 #block-9fb7ae11-8567-470a-b838-708cd2da4546 a { color: inherit; font-size: inherit; font-weight: inherit; line-height: inherit; text-transform: inherit; }

ISOPHALIC POLYESTER RESIN SYSTEM

#shopify-section-pservice_2 #block-58e9c5a2-0936-4af2-b708-3c633d7f3576 {

margin: auto;

padding: 0;

}

@media(max-width: 991px) {

#shopify-section-pservice_2 #block-58e9c5a2-0936-4af2-b708-3c633d7f3576 {

margin: 0;

padding: 0;

}

}

@media(max-width: 767px) {

#shopify-section-pservice_2 #block-58e9c5a2-0936-4af2-b708-3c633d7f3576 {

margin: 0;

padding: 0;

}

}

#shopify-section-pservice_2 #block-58e9c5a2-0936-4af2-b708-3c633d7f3576 .addon-image-content { overflow: hidden; }

#shopify-section-pservice_2 #block-58e9c5a2-0936-4af2-b708-3c633d7f3576 .addon-image-content img {

border-radius: 500px;

max-width: 900px;

margin: ;

}

#shopify-section-pservice_2 #block-58e9c5a2-0936-4af2-b708-3c633d7f3576 .addon-image-content.l img { float: left; }

#shopify-section-pservice_2 #block-58e9c5a2-0936-4af2-b708-3c633d7f3576 .addon-image-content.r img { float: right; }

@media(max-width: 991px) {

#shopify-section-pservice_2 #block-58e9c5a2-0936-4af2-b708-3c633d7f3576 .addon-image-content img { margin: 0; max-width: 100%; }

}

@media(max-width: 767px) {

#shopify-section-pservice_2 #block-58e9c5a2-0936-4af2-b708-3c633d7f3576 .addon-image-content img { margin: 0; max-width: 100%; }

}

#shopify-section-pservice_2 #block-d1fa6fe4-d218-443d-aa5b-2b2e18ffe7a6 {

margin: auto;

padding: 0;

}

@media(max-width: 991px) {

#shopify-section-pservice_2 #block-d1fa6fe4-d218-443d-aa5b-2b2e18ffe7a6 {

margin: 0;

padding: 0;

}

}

@media(max-width: 767px) {

#shopify-section-pservice_2 #block-d1fa6fe4-d218-443d-aa5b-2b2e18ffe7a6 {

margin: 0;

padding: 0;

}

}

#shopify-section-pservice_2 #block-d1fa6fe4-d218-443d-aa5b-2b2e18ffe7a6 {

color: ;

font-size: 14px;

font-weight: 400;

line-height: 24px;

letter-spacing: 0px;

border-radius: 0px;

}

@media(max-width: 991px) {

#shopify-section-pservice_2 #block-d1fa6fe4-d218-443d-aa5b-2b2e18ffe7a6 { font-size: 14px; line-height: 24px; }

}

@media(max-width: 767px) {

#shopify-section-pservice_2 #block-d1fa6fe4-d218-443d-aa5b-2b2e18ffe7a6 { font-size: 14px; line-height: 24px; }

}

#shopify-section-pservice_2 #block-d1fa6fe4-d218-443d-aa5b-2b2e18ffe7a6:hover,

#shopify-section-pservice_2 #block-d1fa6fe4-d218-443d-aa5b-2b2e18ffe7a6:focus,

#shopify-section-pservice_2 #block-d1fa6fe4-d218-443d-aa5b-2b2e18ffe7a6:active {

background-color: ;

border-color: ;

color: ;

}

#shopify-section-pservice_2 #block-d1fa6fe4-d218-443d-aa5b-2b2e18ffe7a6 .addon-heading,

#shopify-section-pservice_2 #block-d1fa6fe4-d218-443d-aa5b-2b2e18ffe7a6 a { color: inherit; font-size: inherit; font-weight: inherit; line-height: inherit; text-transform: inherit; }

VINYL ESTER RESIN SYSTEM

#shopify-section-pservice_2 #block-543de0bf-8f2d-4100-ba36-9dddb89a729e {

margin: auto;

padding: 0;

}

@media(max-width: 991px) {

#shopify-section-pservice_2 #block-543de0bf-8f2d-4100-ba36-9dddb89a729e {

margin: 0;

padding: 0;

}

}

@media(max-width: 767px) {

#shopify-section-pservice_2 #block-543de0bf-8f2d-4100-ba36-9dddb89a729e {

margin: 0;

padding: 0;

}

}

#shopify-section-pservice_2 #block-543de0bf-8f2d-4100-ba36-9dddb89a729e .addon-image-content { overflow: hidden; }

#shopify-section-pservice_2 #block-543de0bf-8f2d-4100-ba36-9dddb89a729e .addon-image-content img {

border-radius: 500px;

max-width: 900px;

margin: ;

}

#shopify-section-pservice_2 #block-543de0bf-8f2d-4100-ba36-9dddb89a729e .addon-image-content.l img { float: left; }

#shopify-section-pservice_2 #block-543de0bf-8f2d-4100-ba36-9dddb89a729e .addon-image-content.r img { float: right; }

@media(max-width: 991px) {

#shopify-section-pservice_2 #block-543de0bf-8f2d-4100-ba36-9dddb89a729e .addon-image-content img { margin: 0; max-width: 100%; }

}

@media(max-width: 767px) {

#shopify-section-pservice_2 #block-543de0bf-8f2d-4100-ba36-9dddb89a729e .addon-image-content img { margin: 0; max-width: 100%; }

}

#shopify-section-pservice_2 #block-7c0dbfcb-d31c-4038-9c1a-77c932d79b10 {

margin: auto;

padding: 0;

}

@media(max-width: 991px) {

#shopify-section-pservice_2 #block-7c0dbfcb-d31c-4038-9c1a-77c932d79b10 {

margin: 0;

padding: 0;

}

}

@media(max-width: 767px) {

#shopify-section-pservice_2 #block-7c0dbfcb-d31c-4038-9c1a-77c932d79b10 {

margin: 0;

padding: 0;

}

}

#shopify-section-pservice_2 #block-7c0dbfcb-d31c-4038-9c1a-77c932d79b10 {

color: ;

font-size: 14px;

font-weight: 400;

line-height: 40px;

letter-spacing: 0px;

border-radius: 0px;

}

@media(max-width: 991px) {

#shopify-section-pservice_2 #block-7c0dbfcb-d31c-4038-9c1a-77c932d79b10 { font-size: 14px; line-height: 24px; }

}

@media(max-width: 767px) {

#shopify-section-pservice_2 #block-7c0dbfcb-d31c-4038-9c1a-77c932d79b10 { font-size: 14px; line-height: 24px; }

}

#shopify-section-pservice_2 #block-7c0dbfcb-d31c-4038-9c1a-77c932d79b10:hover,

#shopify-section-pservice_2 #block-7c0dbfcb-d31c-4038-9c1a-77c932d79b10:focus,

#shopify-section-pservice_2 #block-7c0dbfcb-d31c-4038-9c1a-77c932d79b10:active {

background-color: ;

border-color: ;

color: ;

}

#shopify-section-pservice_2 #block-7c0dbfcb-d31c-4038-9c1a-77c932d79b10 .addon-heading,

#shopify-section-pservice_2 #block-7c0dbfcb-d31c-4038-9c1a-77c932d79b10 a { color: inherit; font-size: inherit; font-weight: inherit; line-height: inherit; text-transform: inherit; }

SOME INTERESTING FACTS ABOUT FIBREGLASS GRATING

#shopify-section-pservice_2 #block-93331377-d463-4b90-b0ad-2c0a1163d5d7 {

margin: auto;

padding: 0;

}

@media(max-width: 991px) {

#shopify-section-pservice_2 #block-93331377-d463-4b90-b0ad-2c0a1163d5d7 {

margin: 0;

padding: 0;

}

}

@media(max-width: 767px) {

#shopify-section-pservice_2 #block-93331377-d463-4b90-b0ad-2c0a1163d5d7 {

margin: 0;

padding: 0;

}

}

#shopify-section-pservice_2 #block-93331377-d463-4b90-b0ad-2c0a1163d5d7 {

color: ;

font-size: 14px;

font-weight: 400;

line-height: 24px;

letter-spacing: 0px;

border-radius: 0px;

}

@media(max-width: 991px) {

#shopify-section-pservice_2 #block-93331377-d463-4b90-b0ad-2c0a1163d5d7 { font-size: 14px; line-height: 24px; }

}

@media(max-width: 767px) {

#shopify-section-pservice_2 #block-93331377-d463-4b90-b0ad-2c0a1163d5d7 { font-size: 14px; line-height: 24px; }

}

#shopify-section-pservice_2 #block-93331377-d463-4b90-b0ad-2c0a1163d5d7:hover,

#shopify-section-pservice_2 #block-93331377-d463-4b90-b0ad-2c0a1163d5d7:focus,

#shopify-section-pservice_2 #block-93331377-d463-4b90-b0ad-2c0a1163d5d7:active {

background-color: ;

border-color: ;

color: ;

}

#shopify-section-pservice_2 #block-93331377-d463-4b90-b0ad-2c0a1163d5d7 .addon-heading,

#shopify-section-pservice_2 #block-93331377-d463-4b90-b0ad-2c0a1163d5d7 a { color: inherit; font-size: inherit; font-weight: inherit; line-height: inherit; text-transform: inherit; }

- Fibreglass Grating has low embodied energy and is static-free.

- Fibreglass Grating is a brilliant insulator against heat and cold.

- Fibreglass Grating helps to conserve energy which would help in reducing operating costs.

- Fibreglass Grating is an extremely durable material with a long-life cycle, reducing

replacement costs and keeping more materials out of the landfill.

- Fibreglass Grating experiences low electrical conductivity making it perfect for industries

where electricity could pose a risk.

#shopify-section-pservice_2 #block-1ce12758-d6bd-4198-8541-82c2532ffc28 {

margin: auto;

padding: -10px;

}

@media(max-width: 991px) {

#shopify-section-pservice_2 #block-1ce12758-d6bd-4198-8541-82c2532ffc28 {

margin: 0;

padding: 0;

}

}

@media(max-width: 767px) {

#shopify-section-pservice_2 #block-1ce12758-d6bd-4198-8541-82c2532ffc28 {

margin: 0;

padding: 0;

}

}

#shopify-section-pservice_2 #block-1ce12758-d6bd-4198-8541-82c2532ffc28 {

color: ;

font-size: 14px;

font-weight: 400;

line-height: 40px;

letter-spacing: 0px;

border-radius: 0px;

}

@media(max-width: 991px) {

#shopify-section-pservice_2 #block-1ce12758-d6bd-4198-8541-82c2532ffc28 { font-size: 14px; line-height: 24px; }

}

@media(max-width: 767px) {

#shopify-section-pservice_2 #block-1ce12758-d6bd-4198-8541-82c2532ffc28 { font-size: 14px; line-height: 24px; }

}

#shopify-section-pservice_2 #block-1ce12758-d6bd-4198-8541-82c2532ffc28:hover,

#shopify-section-pservice_2 #block-1ce12758-d6bd-4198-8541-82c2532ffc28:focus,

#shopify-section-pservice_2 #block-1ce12758-d6bd-4198-8541-82c2532ffc28:active {

background-color: ;

border-color: ;

color: ;

}

#shopify-section-pservice_2 #block-1ce12758-d6bd-4198-8541-82c2532ffc28 .addon-heading,

#shopify-section-pservice_2 #block-1ce12758-d6bd-4198-8541-82c2532ffc28 a { color: inherit; font-size: inherit; font-weight: inherit; line-height: inherit; text-transform: inherit; }

IMPORTANT SAFETY FACTORS ABOUT FIBREGLASS GRATING

#shopify-section-pservice_2 #block-984f43c7-dfbc-46ec-b9c9-b057b8e1bbfe {

margin: auto;

padding: 0;

}

@media(max-width: 991px) {

#shopify-section-pservice_2 #block-984f43c7-dfbc-46ec-b9c9-b057b8e1bbfe {

margin: 0;

padding: 0;

}

}

@media(max-width: 767px) {

#shopify-section-pservice_2 #block-984f43c7-dfbc-46ec-b9c9-b057b8e1bbfe {

margin: 0;

padding: 0;

}

}

#shopify-section-pservice_2 #block-984f43c7-dfbc-46ec-b9c9-b057b8e1bbfe {

color: ;

font-size: 14px;

font-weight: 400;

line-height: 24px;

letter-spacing: 0px;

border-radius: 0px;

}

@media(max-width: 991px) {

#shopify-section-pservice_2 #block-984f43c7-dfbc-46ec-b9c9-b057b8e1bbfe { font-size: 14px; line-height: 24px; }

}

@media(max-width: 767px) {

#shopify-section-pservice_2 #block-984f43c7-dfbc-46ec-b9c9-b057b8e1bbfe { font-size: 14px; line-height: 24px; }

}

#shopify-section-pservice_2 #block-984f43c7-dfbc-46ec-b9c9-b057b8e1bbfe:hover,

#shopify-section-pservice_2 #block-984f43c7-dfbc-46ec-b9c9-b057b8e1bbfe:focus,

#shopify-section-pservice_2 #block-984f43c7-dfbc-46ec-b9c9-b057b8e1bbfe:active {

background-color: ;

border-color: ;

color: ;

}

#shopify-section-pservice_2 #block-984f43c7-dfbc-46ec-b9c9-b057b8e1bbfe .addon-heading,

#shopify-section-pservice_2 #block-984f43c7-dfbc-46ec-b9c9-b057b8e1bbfe a { color: inherit; font-size: inherit; font-weight: inherit; line-height: inherit; text-transform: inherit; }

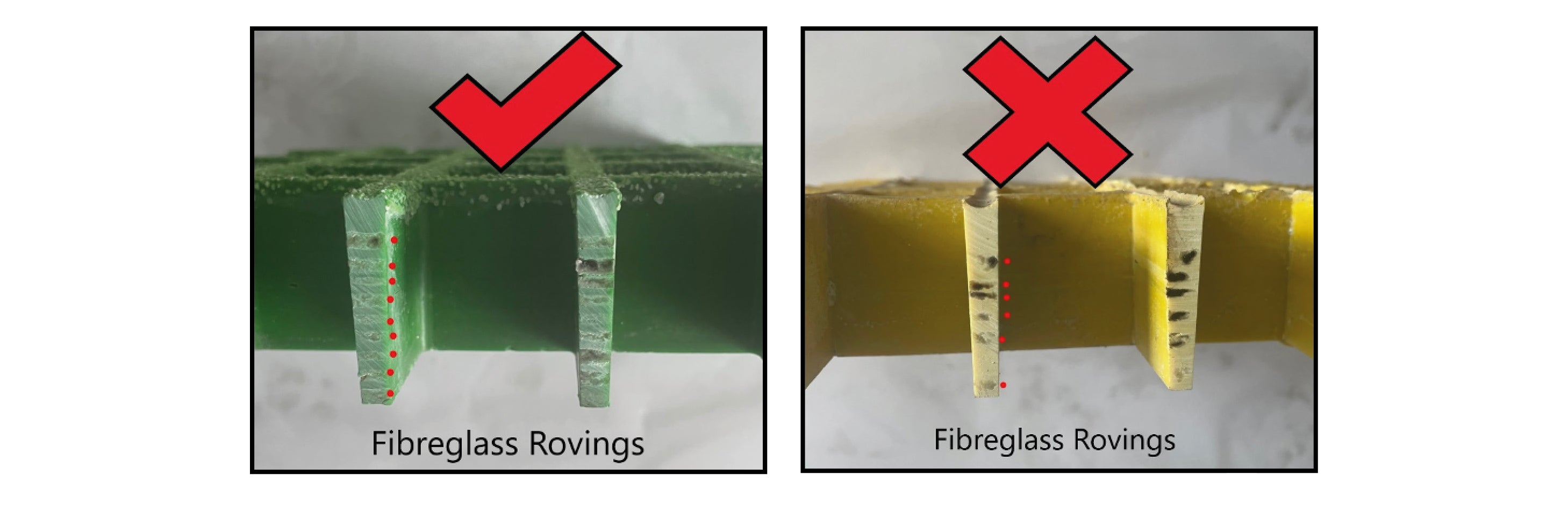

- It is important to remember that it is not what the fibreglass grating looks like on the outside, but more of what it looks like on the inside

- The fibreglass rovings are the strength of the fibreglass grating – make sure the correct number of rovings are used when ordering, making sure there are minimal gaps in-between each roving.

- If the panel is not manufactured in the correct manner, the end result will not be positive and the lifespan of the grating will be severely compromised – especially where the grating panels are used for walkways

- It is also important to get resin certificates with your orders as there are countless resin systems that can be used. If the incorrect resin system is used, it will essentially lead to failure of the fibreglass grating panels

- When cutting fibreglass grating on site, remember to do touch ups on cut-outs immediately with resin filler. Without this, the fibreglass grating can start to corrode from the inside of the cut-out, causing cracks which are not visible to the naked eye and will essentially corrode from the inside to the outside of the grating panel

#shopify-section-pservice_2 #block-835b8780-c290-4557-b373-26a3b5d91d4b {

margin: auto;

padding: 0;

}

@media(max-width: 991px) {

#shopify-section-pservice_2 #block-835b8780-c290-4557-b373-26a3b5d91d4b {

margin: 0;

padding: 0;

}

}

@media(max-width: 767px) {

#shopify-section-pservice_2 #block-835b8780-c290-4557-b373-26a3b5d91d4b {

margin: 0;

padding: 0;

}

}

#shopify-section-pservice_2 #block-835b8780-c290-4557-b373-26a3b5d91d4b .addon-image-content { overflow: hidden; }

#shopify-section-pservice_2 #block-835b8780-c290-4557-b373-26a3b5d91d4b .addon-image-content img {

border-radius: 500px;

max-width: 900px;

margin: ;

}

#shopify-section-pservice_2 #block-835b8780-c290-4557-b373-26a3b5d91d4b .addon-image-content.l img { float: left; }

#shopify-section-pservice_2 #block-835b8780-c290-4557-b373-26a3b5d91d4b .addon-image-content.r img { float: right; }

@media(max-width: 991px) {

#shopify-section-pservice_2 #block-835b8780-c290-4557-b373-26a3b5d91d4b .addon-image-content img { margin: 0; max-width: 100%; }

}

@media(max-width: 767px) {

#shopify-section-pservice_2 #block-835b8780-c290-4557-b373-26a3b5d91d4b .addon-image-content img { margin: 0; max-width: 100%; }

}

#shopify-section-pservice_2 #block-80e10278-11e6-47bf-870f-8e1cca4138c0 {

margin: auto;

padding: 0;

}

@media(max-width: 991px) {

#shopify-section-pservice_2 #block-80e10278-11e6-47bf-870f-8e1cca4138c0 {

margin: 0;

padding: 0;

}

}

@media(max-width: 767px) {

#shopify-section-pservice_2 #block-80e10278-11e6-47bf-870f-8e1cca4138c0 {

margin: 0;

padding: 0;

}

}

#shopify-section-pservice_2 #block-80e10278-11e6-47bf-870f-8e1cca4138c0 .addon-menu ul.circled li.bg { line-height: 36px; background: #211212; }

#shopify-section-pservice_2 #block-80e10278-11e6-47bf-870f-8e1cca4138c0 .addon-menu ul.circled li.bg:hover,

#shopify-section-pservice_2 #block-80e10278-11e6-47bf-870f-8e1cca4138c0 .addon-menu ul.circled li.bg:focus,

#shopify-section-pservice_2 #block-80e10278-11e6-47bf-870f-8e1cca4138c0 .addon-menu ul.circled li.bg:active { background: #e40425; }

#shopify-section-pservice_2 #block-80e10278-11e6-47bf-870f-8e1cca4138c0 .addon-menu ul.circled li.bg:before { color: #ffffff; }

#shopify-section-pservice_2 #block-80e10278-11e6-47bf-870f-8e1cca4138c0 .addon-menu ul.circled li.bg:hover:before,

#shopify-section-pservice_2 #block-80e10278-11e6-47bf-870f-8e1cca4138c0 .addon-menu ul.circled li.bg:focus:before,

#shopify-section-pservice_2 #block-80e10278-11e6-47bf-870f-8e1cca4138c0 .addon-menu ul.circled li.bg:active:before { color: #ffffff; }

#shopify-section-pservice_2 #block-80e10278-11e6-47bf-870f-8e1cca4138c0 .addon-menu ul.circled li.bg a { color: #ffffff; }

#shopify-section-pservice_2 #block-80e10278-11e6-47bf-870f-8e1cca4138c0 .addon-menu ul.circled li.bg:hover a,

#shopify-section-pservice_2 #block-80e10278-11e6-47bf-870f-8e1cca4138c0 .addon-menu ul.circled li.bg:focus a,

#shopify-section-pservice_2 #block-80e10278-11e6-47bf-870f-8e1cca4138c0 .addon-menu ul.circled li.bg:active a { color: #ffffff; }

#shopify-section-pservice_2 #block-1369077c-7073-4cc4-87d6-9d4ac63a310b {

margin: auto;

padding: 0;

}

@media(max-width: 991px) {

#shopify-section-pservice_2 #block-1369077c-7073-4cc4-87d6-9d4ac63a310b {

margin: 0;

padding: 0;

}

}

@media(max-width: 767px) {

#shopify-section-pservice_2 #block-1369077c-7073-4cc4-87d6-9d4ac63a310b {

margin: 0;

padding: 0;

}

}

#shopify-section-pservice_2 #block-1369077c-7073-4cc4-87d6-9d4ac63a310b {

color: ;

font-size: 20px;

font-weight: 400;

line-height: 40px;

letter-spacing: 0px;

border-radius: 0px;

}

@media(max-width: 991px) {

#shopify-section-pservice_2 #block-1369077c-7073-4cc4-87d6-9d4ac63a310b { font-size: 14px; line-height: 24px; }

}

@media(max-width: 767px) {

#shopify-section-pservice_2 #block-1369077c-7073-4cc4-87d6-9d4ac63a310b { font-size: 14px; line-height: 24px; }

}

#shopify-section-pservice_2 #block-1369077c-7073-4cc4-87d6-9d4ac63a310b:hover,

#shopify-section-pservice_2 #block-1369077c-7073-4cc4-87d6-9d4ac63a310b:focus,

#shopify-section-pservice_2 #block-1369077c-7073-4cc4-87d6-9d4ac63a310b:active {

background-color: ;

border-color: ;

color: ;

}

#shopify-section-pservice_2 #block-1369077c-7073-4cc4-87d6-9d4ac63a310b .addon-heading,

#shopify-section-pservice_2 #block-1369077c-7073-4cc4-87d6-9d4ac63a310b a { color: inherit; font-size: inherit; font-weight: inherit; line-height: inherit; text-transform: inherit; }

Contact us today for a quote

STAY IN TOUCH!

SUBSCRIBE TO OUR NEWSLETTER

© 2021 Magnus Steel. All rights reserved.