Expanded Metal

Expanded Metal

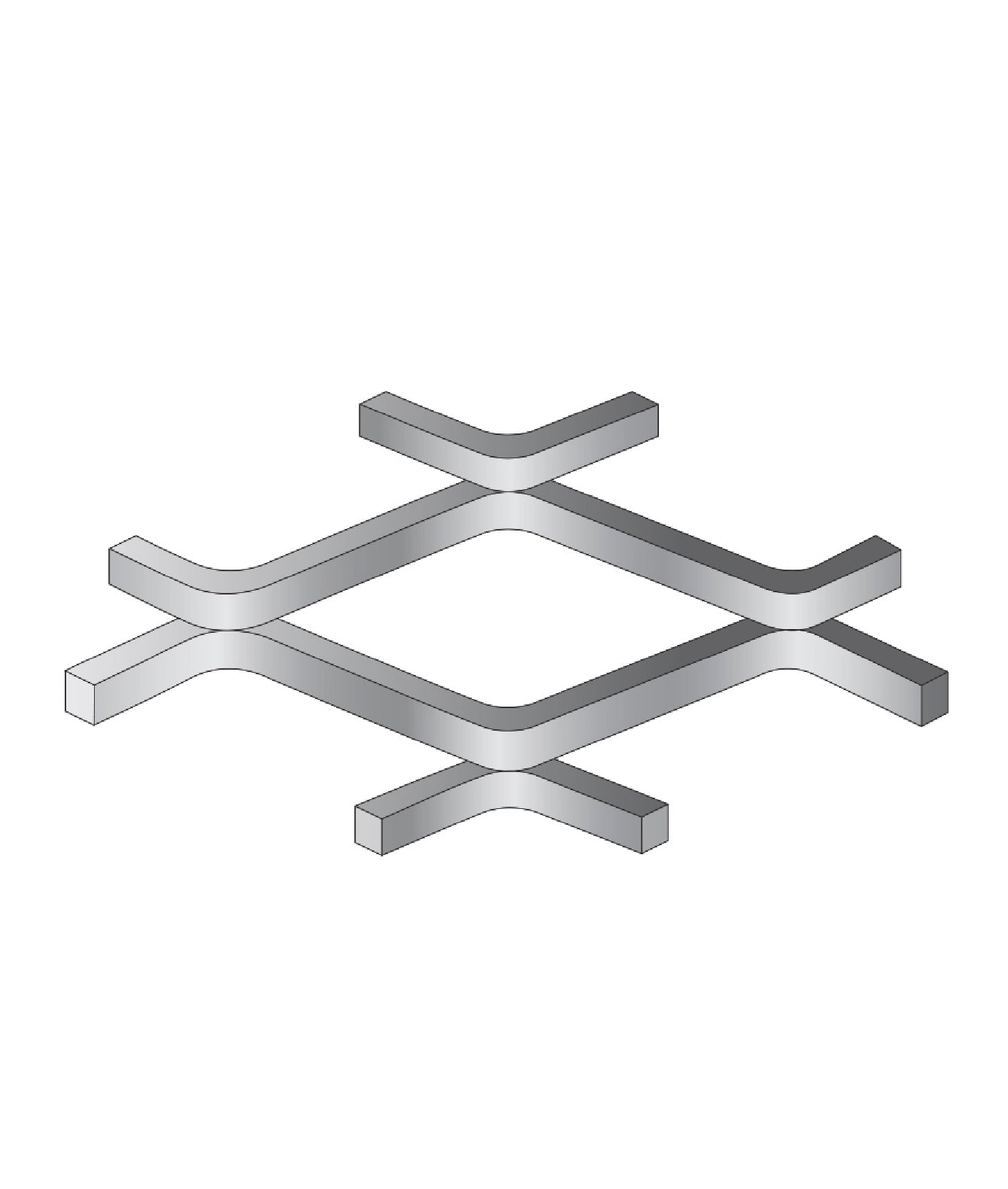

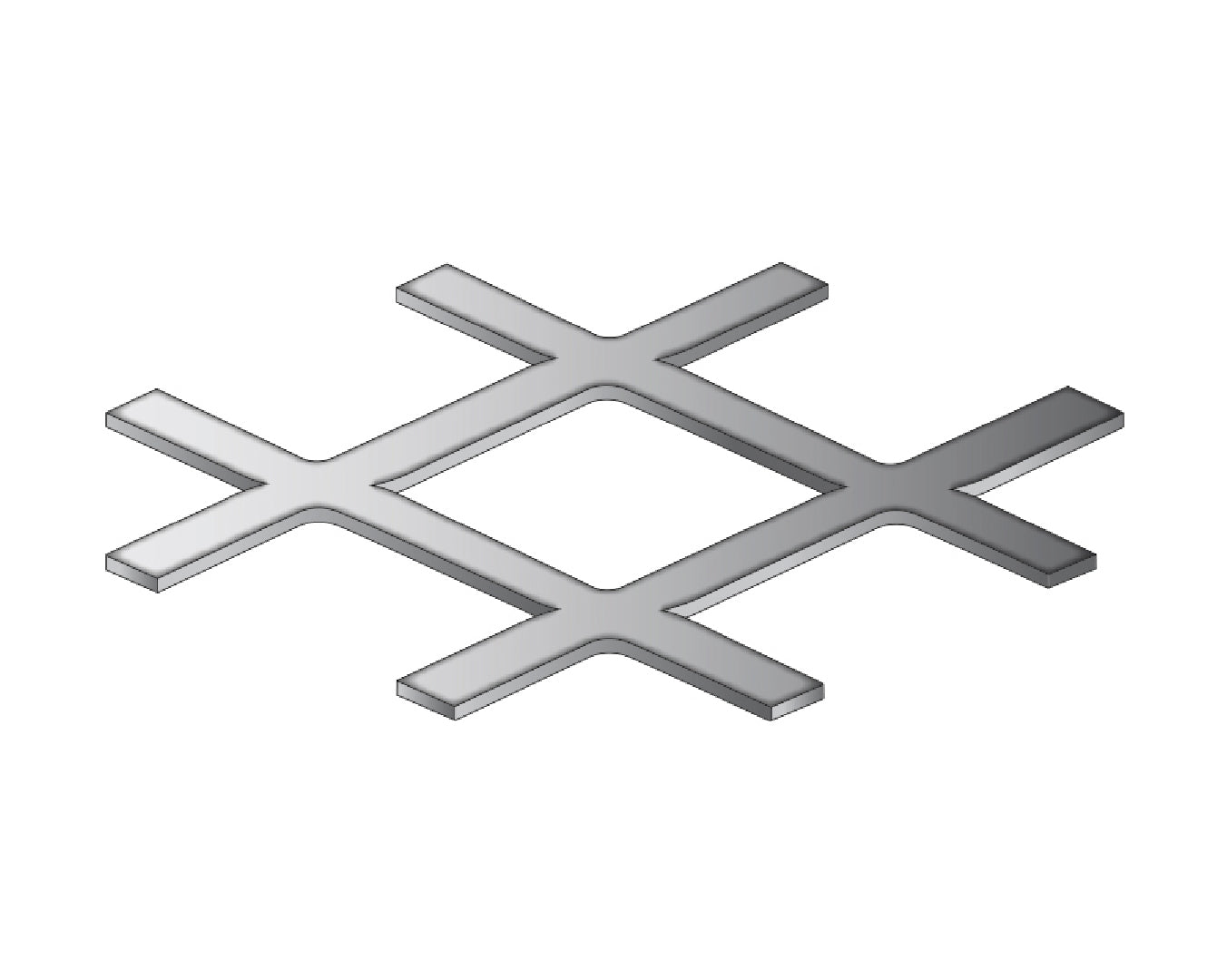

The process of manufacturing expanded metal usually begins with a sheet of metal or steel coil that is fed into a machine that is designed to cut and expand the metal into a pattern of diamond-shaped openings. This is done by cutting the sheet with a press that shears and stretches the metal simultaneously. No steel is lost during the manufacturing process. The pattern is then held in place with a series of die sets. After the cutting is complete, the expanded metal is then flattened and straightened, or alternatively supplied in a raised surface. Finally, the expanded metal is then coated with a protective finish such as paint, powder coating, or galvanizing to protect against corrosion and other weathering effects.

Expanded metal is a versatile and durable material that can be used for a wide range of applications. It is made from a sheet of metal that is cut and stretched to create a pattern of diamond-shaped openings. The openings in the metal allow air, light, and liquid to pass through, making expanded metal ideal for a variety of applications, from security fencing to building facades.

Expanded metal is available in a variety of materials, including steel, galvanized and stainless steel. Each material offers different levels of strength and durability, making it easy to find a material that suits your needs. Steel expanded metal is strong and durable, making it a great choice for building facades and other structural applications. Stainless steel expanded metal is highly corrosion-resistant and has a sleek, modern look, making it perfect for architectural applications.

Expanded metal is an economical choice, as it is lightweight and easy to install. It is also easy to cut and shape, allowing you to customize it for your application. Plus, expanded metal can be powder-coated for added protection and color, making it a great choice for decorative applications.

Expanded metal is an incredibly durable material that can stand up to harsh weather conditions, making it a great choice for outdoor applications. It is also easy to clean and maintain, making it ideal for applications where hygiene is a priority.

Expanded Metal Braai Grid

Expanded metal braai grid is a type of braai grid that is made from a sheet of metal that has been expanded or flattened. This type of grid is also lightweight and easy to clean. It is also more affordable than other types of grids, making it a popular choice for outdoor grills.

Different types of braai grids are available in different sizes, shapes, and materials. Some grids are designed to fit over charcoal or wood fires while others are made to be used on gas grills. Some grids have adjustable heights, allowing food to be cooked closer or farther away from the heat source. Other features include handles for easy removal from the fire, as well as removable grates for easy cleaning.

Expanded Metal Walkway Mesh

Expanded Metal Walkway Mesh is made from a single piece of metal that has been expanded and cut into a hexagonal and diamond shaped pattern. The pattern is designed to allow more air, light, and water to pass through than other types of grating. The diamond-shaped openings also provide more traction, making walkway expanded metal mesh ideal for use in areas where slip resistance is important.

Walkway expanded metal mesh is used in a variety of applications, such as staircases, ramps, bridges, and other pedestrian walkways. It is also used in industrial applications, such as shelves, flooring, and walkways in warehouses and factories. The mesh can be used in a variety of materials, such as mild steel, stainless steel, or galvanized steel.

Because of its flexibility, walkway expanded metal mesh is also used in building and construction projects. It can be used as a decorative feature to enhance the appearance of a room or building. It can also be used to strengthen the structure of a building by providing support for walls and floors.

Walkway expanded metal mesh is also used for safety purposes, such as reinforcing decks and providing additional support. It can also be used to provide a barrier to keep people from falling off of balconies or walkways. In addition, it can be used to protect against objects that could potentially fall from height and cause injury.

Walkway expanded metal mesh is also cost-effective and durable, making it an ideal choice for a variety of projects. It is also easy to install, which makes it a great choice for DIY projects.

How to order Expanded Metal

- Specify quantity of sheets required

- Specify size of sheet (standard size is 1200 x 2400)

- Specify reference code of Expanded Metal

- Specify the material you require

- State whether the material is flattened or raised

Expanded Metal Specifications and Codes

| CODE |

SIZE OF MESH SWM X LWM |

STRAND |

WEIGHT KG / 1.2 X 2.4 |

|

|

|

WIDTH |

THICKNESS |

|

|||

|

|||||

|

36R-A |

3 X 6 |

1.0 |

0.6 |

7.44 |

|

|

510R-A |

5 X 10 |

1.0 |

1.0 |

8.22 |

|

|

820R-A |

8 X 20 |

2.0 |

1.0 |

10.17 |

|

|

1630R-A |

16 X 30 |

2.5 |

1.3 |

9.49 |

|

|

1840R-A |

18 X 40 |

2.5 |

1.3 |

8.43 |

|

|

1840R-C |

18 X 40 |

2.6 |

2.4 |

16.27 |

|

|

3055R-D |

30 X 55 |

2.6 |

2.9 |

11.79 |

|

|

3060R-D |

30 X 60 |

2.7 |

2.9 |

12.25 |

|

|

3060R-E |

30 X 60 |

4.5 |

4.4 |

30.34 |

|

|

3680R-D |

36 X 80 |

2.6 |

2.9 |

9.83 |

|

|

5080R-D |

50 X 80 |

2.6 |

2.9 |

7.08 |

|

|

48115R-E |

48 X 115 |

4.0 |

4.4 |

16.86 |

|

|

18115R-EE |

48 X 115 |

4.8 |

4.4 |

20.02 |

|

|

|||||

|

510F-A |

5 X 10 |

1.2 |

1.0 |

8.22 |

|

|

820F-A |

8 X 20 |

2.0 |

1.0 |

10.17 |

|

|

1630F-A |

16 X 30 |

2.6 |

1.3 |

9.91 |

|

|

1630F-B |

16 X 30 |

2.6 |

1.8 |

11.60 |

|

|

2040F-A |

20 X 40 |

2.6 |

1.3 |

8.81 |

|

|

2040F-C |

20 X 40 |

2.6 |

2.4 |

16.27 |

|

|

3055F-A |

30 X 55 |

2.6 |

1.3 |

5.26 |

|

|

3055F-B |

30 X 55 |

2.6 |

1.7 |

6.88 |

|

|

3055F-C |

30 X 55 |

3.8 |

2.4 |

14.27 |

|

|

3055F-D |

30 X 55 |

2.6 |

2.9 |

11.79 |

|

|

3055F-DD |

30 X 55 |

3.8 |

2.9 |

17.27 |

|

|

3055F-PIG |

30 X 55 |

8.7 |

2.9 |

39.47 |

|

|

3080F-C |

30 X 80 |

4.5 |

2.5 |

12 |

|

|

5080F-C |

50 X 80 |

3.8 |

2.5 |

9.01 |

|

|

|||||

|

4014W-A |

40 X 140 |

6.0 |

4.0 |

24.56 |

|

|

3512W-A |

35 X 120 |

6.0 |

4.0 |

30.95 |

|

|

3512W-B |

35 X 120 |

8.0 |

4.5 |

44.08 |

|

|

3512W-C |

35 X 120 |

10.0 |

4.0 |

52.35 |

|

|

3512W-D |

35 X 120 |

10.0 |

5.0 |

64.32 |

|

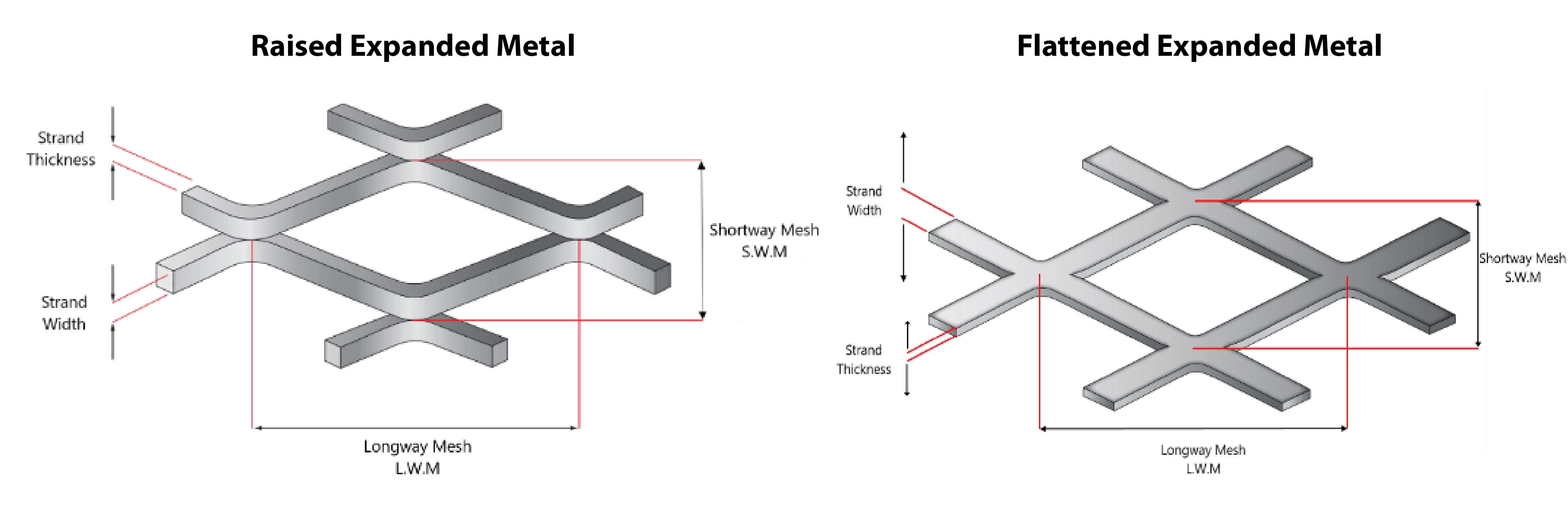

EXPANDED METAL TERMINOLOGY

S.W.M = Short way of Mesh:

This is the size measured across the short way of the diamond mesh from centre-to-centre of the joints.L.W.M = Long way of Mesh:

This is the size measured across the long way of the diamond mesh from centre-to-centre of the joints.Strand Width:

The size of the strand measured at right angles to its thickness.Strand Thickness:

The thickness of the sheet before the expanding process takes place.EXPANDED METAL TOLERANCES:

L.W.M =

NominalL.W.M =

(a) Not greater than 10mm: ± 1mm (b) Not less than 10mm and not greater than 50mm: ± 3mm (c) Greater than 50mm: ±5mm. Strand Width: ± 10 % Strand Thickness: Subject to Mittal’s tolerance, except for flattened types which shall be at least equal to the nominal original thickness of the material of manufacture within 20%, measured at the knuckle.USES FOR EXPANDED METAL

USES FOR EXPANDED METAL

Although there are countless uses for expanded metal, some examples include:

Conveyor Walkways | Braai Grids | Filters | Screening | Architectural Design | Guards | Security | Acoustics

| Dust bins | Architectural Fencing | Security Fencing | Window and Door Security | Air Intake Screens

| Interior Partitions and Barriers | Cab/Truck Dividers Trailers | Concrete Reinforcement | Drive and Sidewalk Gates | Light Diffusers | Machine Guards | Patio Furniture | Landscape and Utility Carts | Fire Escapes | Fuel Cells | Gaskets

USES FOR EXPANDED METAL

Although there are countless uses for expanded metal, some examples include:

Conveyor Walkways | Braai Grids | Filters | Screening | Architectural Design | Guards | Security | Acoustics

| Dust bins | Architectural Fencing | Security Fencing | Window and Door Security | Air Intake Screens

| Interior Partitions and Barriers | Cab/Truck Dividers Trailers | Concrete Reinforcement | Drive and Sidewalk Gates | Light Diffusers | Machine Guards | Patio Furniture | Landscape and Utility Carts | Fire Escapes | Fuel Cells | Gaskets Expanded Metal can be manufactured in Mild Steel, Galvanised, 3cr12, Stainless Steel and Aluminium.

STAY IN TOUCH!

SUBSCRIBE TO OUR NEWSLETTER

© 2021 Magnus Steel. All rights reserved.