Fibreglass Grating

What is Fibreglass Grating?

Fiberglass Grating is an incredibly versatile and durable product that can be used in a variety of applications. Not only is it strong and lightweight, but it also offers a high level of corrosion resistance and will not rot, rust or corrode like traditional materials. It is also low-maintenance and cost-effective, making it a great choice for any application.

Fiberglass grating is composed of a strong, lightweight, and corrosion-resistant material that can be used in many different applications. Fiberglass grating is available in a variety of sizes and styles, including molded, pultruded, and gritted varieties, that offer a range of advantages and benefits.

Molded Fiberglass Grating is designed for easy installation and is the most economical type of fiberglass grating. This type is made from a pre-existing mold and offers a uniform surface with a high load capacity. It is perfect for use in areas where drainage is important and is often used in walkways and decks.

Pultruded Fiberglass Grating is a stronger and stiffer grating option that is perfect for areas where strength and stability are key. This type of grating is made by combining fiberglass strands and resin under high pressure, which results in a very durable product. It is often used in areas that require a more substantial material, such as drainage systems, machine access platforms, and stairways.

No matter what your application, fiberglass grating is an excellent choice that offers a high level of durability and corrosion resistance. With its versatile design and range of styles, this product is a great choice for any project.

When was Fibreglass Grating first introduced?

Fiberglass grating was first introduced in the early 1950s. It was developed as a lightweight, corrosion-resistant alternative to metal grating.

What is the manufacturing process of Fibreglass Grating?

The manufacturing process of fibreglass grating typically includes the following steps:

- Preparation - This includes preparing the raw materials such as glass fibers, resins, and fillers, as well as any necessary additives.

- Molding - During this step, the raw materials are combined and formed into the desired shape of the grating. This may include pressing the mixture into a mold before it hardens.

- Curing - The molded grating is then cured in a heated oven to harden and strengthen the material.

- Finishing - The cured grating is then cut and sanded to the desired shape and size. This may also include adding additional finishes such as aluminum oxide or zinc phosphate.

- Inspection - Once the grating is complete, it is inspected for any defects or weaknesses.

- Packaging - The grating is then packaged for safe transport and delivery.

What are the uses for Fibreglass Grating?

- Industrial & Commercial Flooring: Fibreglass grating is a great choice for industrial and commercial flooring applications due to its superior strength, low weight, and corrosion resistance.

- Walkways & Platforms: Fibreglass grating is an ideal material for creating walkways, platforms, and staircases in industrial and commercial buildings. It offers superior slip resistance, and its light weight makes it easy to install and maintain.

- Anti-Slip Stair Treads: Fibreglass grating can also be used to create anti-slip stair treads, which are a great choice for high-traffic areas where safety is a priority.

- Chemical & Corrosion Resistance: Fibreglass grating is highly resistant to chemicals and corrosion, making it ideal for applications in areas with harsh environmental conditions.

- Drainage & Water Treatment: Fibreglass grating can be used to create drainage channels and water treatment systems, as it is highly resistant to both corrosion and weathering.

- Marine Construction: Fibreglass grating is an ideal material for marine construction applications, as it is highly resistant to corrosion and does not absorb water.

Different types of resin systems for Fibreglass Grating

- Polyester Resin System: This is the most common resin system used in fiberglass grating. It is a low-cost, general-purpose resin system that offers excellent chemical resistance, good mechanical strength, and is relatively easy to work with.

- Isophthalic Resin System: This resin system is designed for applications that require a balance of chemical and mechanical properties. It is more expensive than polyester resin, but the added protection is worth the cost.

- Vinyl Ester Resin System: This resin system is used when greater chemical resistance and mechanical strength are needed. It is more expensive than polyester resin, but the added protection is worth the cost.

- Phenolic Resin System: This resin system is designed for extreme chemical resistance and is used in highly corrosive environments. It is the most expensive resin system and requires specialized fabrication techniques.

When should Fibreglass Grating have UV protection?

Fibreglass grating should have UV protection if it is going to be exposed to direct sunlight or other sources of UV radiation for an extended period of time. UV protection helps to prevent the grating from fading or breaking down due to exposure.

Difference between Polyester Fibreglass Resin and Isophalic Fibreglass Resin in grating?

Isophthalic fibreglass resin has better chemical and corrosion resistance than Polyester fibreglass resin, making it a better choice for applications involving harsh chemicals or environments with a high humidity or salt content. Isophthalic fibreglass resin is also more expensive than polyester fibreglass resin.

Difference between Isophalic Fibreglass Resin and Vinyl Ester Resin in grating?

Vinyl ester resin is superior to isophthalic fibreglass resin in terms of corrosion resistance and mechanical strength. It is also more expensive than isophthalic fibreglass resin. Vinyl ester resin is often used in applications where the grating is exposed to harsh chemicals or environments with a high humidity or salt content.

Difference between Meniscus Surface and Gritted Surface in Fibreglass Grating

The difference between a meniscus surface and a gritted surface in fibreglass grating is that the meniscus surface is a smooth, curved surface while the gritted surface is a textured surface with small raised ridges. The meniscus surface provides a non-slip surface that is ideal for wet, slippery areas, while the gritted surface provides a more aggressive grip, making it better suited for areas that require extra traction.

Interesting facts about Fibreglass Grating

- Fibreglass grating is a lightweight, corrosion-resistant flooring material made from reinforced glass fibres.

- Fibreglass grating is ideal for use in areas exposed to harsh environments, including in chemical processing, water treatment, and food production.

- The grating is available in a variety of colors, shapes, and sizes and is easy to install.

- Fibreglass grating is slip-resistant, which makes it safer to walk on.

- It is also flame-resistant and self-extinguishing, making it suitable for use in areas where there is a risk of fire.

- Fibreglass grating has a high load capacity and is durable, making it suitable for use in areas with heavy foot traffic.

- The material is non-conductive and non-magnetic, making it suitable for use in areas with electrical equipment.

- It is also non-sparking and non-corrosive, making it suitable for use in areas where there is a risk of explosion or chemical spills.

- Fibreglass grating is maintenance-free and can be easily cleaned and sanitized.

How to choose the correct type of Fibreglass Grating

- Determine the application: The first step in choosing the correct type of fiberglass grating is to determine what the grating will be used for. Will it be used in a wet or dry environment? Will it be exposed to chemicals or corrosive elements? Will it need to be load-bearing? By understanding the application, you can begin to narrow down the different types of grating available.

- Compare the different types of grating: There are several different styles of grating available, including molded, pultruded, and bar grating. Each type has its own advantages and disadvantages, so you'll need to compare the different types to determine which one is best suited for your needs.

- Consider the load requirements: If the grating will be used as a load-bearing structure, you'll need to consider its load capacity. Different grating types have different load ratings, so make sure to select a type that can withstand the loads it will be subjected to.

- Choose the right material: Fiberglass grating can be made from different materials, such as polyester, isophalic, vinyl ester, or phenolic resin. Each material has its own advantages and disadvantages, so make sure to select the one that will provide the best performance in your application.

- Consider the installation requirements: Lastly, make sure to consider the installation requirements for the grating. Different grating types require different installation methods, so make sure to choose the type that can be installed most easily and efficiently.

What should happen if Fibreglass Grating is cut-up?

If fibreglass grating is cut-up and then installed on site, it is important to ensure that all edges are sealed with a resin prior to installation to prevent any water or chemical intrusion. It is also important to ensure that all cut edges are sanded to prevent any sharp edges that may cause injury. Additionally, it is important to ensure that the grating is installed according to the manufacturer’s instructions to ensure that the grating is installed correctly and safely.

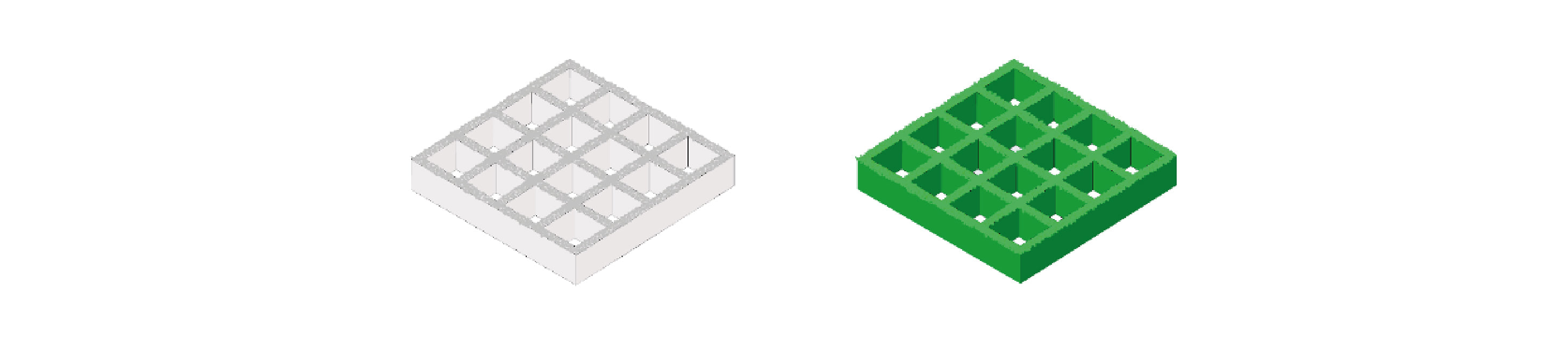

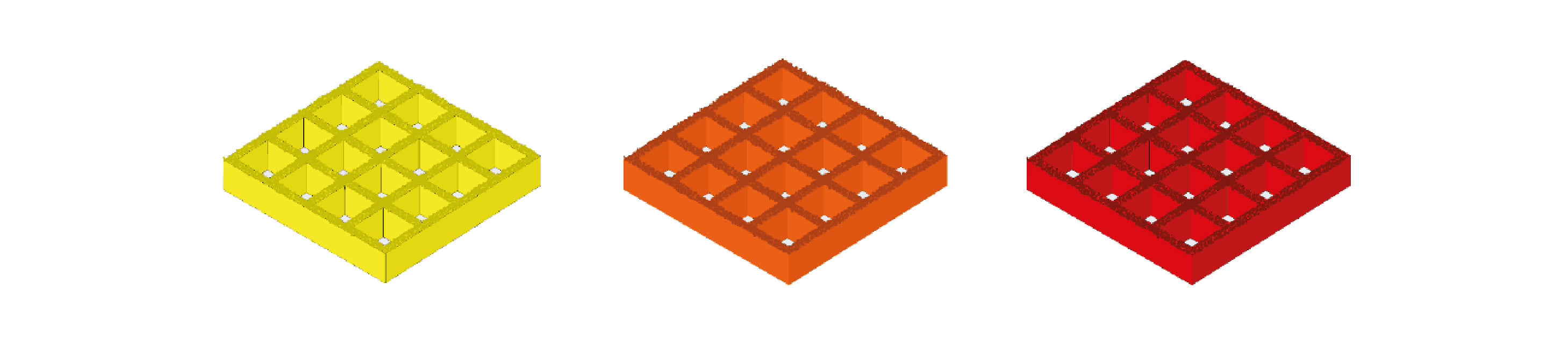

We carry a large quantity of stock of Fibreglass Grating and can provide our customers with the following resin systems:

- Isophalic Polyester (Green and Light Grey)

- Vinyl Ester (Orange, Yellow, Red)

The Magnus Group can supply fibreglass grating panels in the following sizes:

- 2440 x 1220

- 3660 x 1220

Thicknesses of fibreglass grating on offer include:

- 25mm

- 30mm

- 38mm

- 50mm

ISOPHALIC POLYESTER RESIN SYSTEM

VINYL ESTER RESIN SYSTEM

SOME INTERESTING FACTS ABOUT FIBREGLASS GRATING

- Fibreglass Grating has low embodied energy and is static-free.

- Fibreglass Grating is a brilliant insulator against heat and cold.

- Fibreglass Grating helps to conserve energy which would help in reducing operating costs.

- Fibreglass Grating is an extremely durable material with a long-life cycle, reducing

replacement costs and keeping more materials out of the landfill.

- Fibreglass Grating experiences low electrical conductivity making it perfect for industries

where electricity could pose a risk.

IMPORTANT SAFETY FACTORS ABOUT FIBREGLASS GRATING

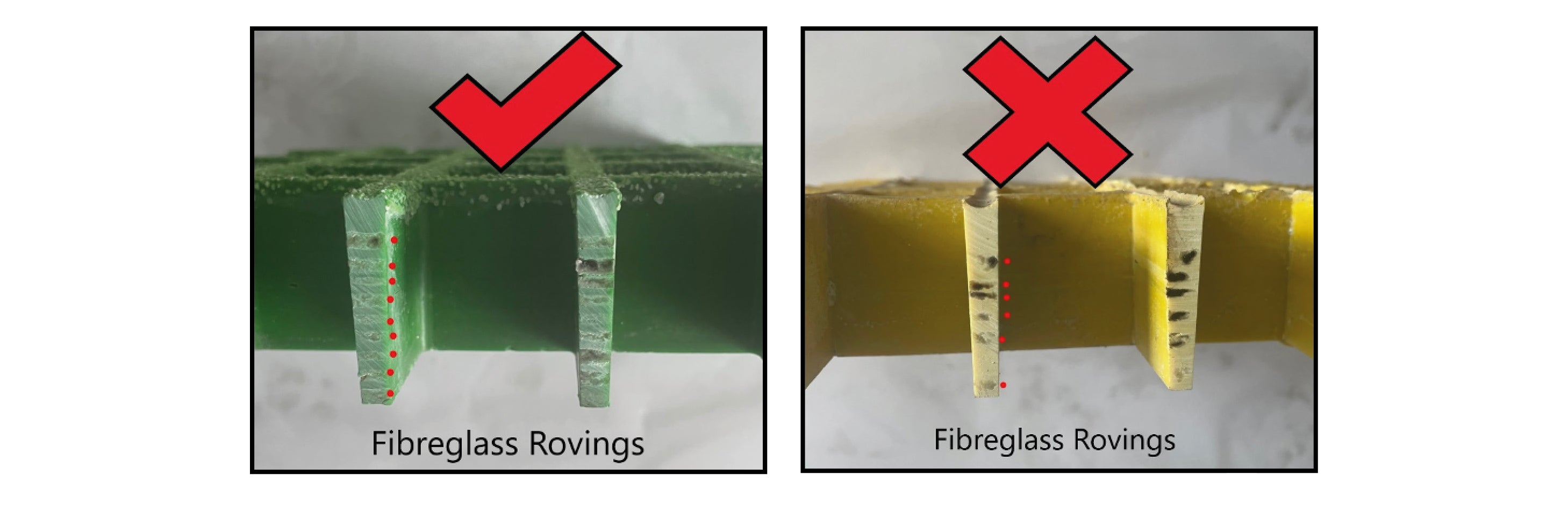

- It is important to remember that it is not what the fibreglass grating looks like on the outside, but more of what it looks like on the inside

- The fibreglass rovings are the strength of the fibreglass grating – make sure the correct number of rovings are used when ordering, making sure there are minimal gaps in-between each roving.

- If the panel is not manufactured in the correct manner, the end result will not be positive and the lifespan of the grating will be severely compromised – especially where the grating panels are used for walkways

- It is also important to get resin certificates with your orders as there are countless resin systems that can be used. If the incorrect resin system is used, it will essentially lead to failure of the fibreglass grating panels

- When cutting fibreglass grating on site, remember to do touch ups on cut-outs immediately with resin filler. Without this, the fibreglass grating can start to corrode from the inside of the cut-out, causing cracks which are not visible to the naked eye and will essentially corrode from the inside to the outside of the grating panel

STAY IN TOUCH!

SUBSCRIBE TO OUR NEWSLETTER

© 2021 Magnus Steel. All rights reserved.